Portable durometer for metals ARW-220

Availability: In Stock

Measure the hardness of metals quickly and easily

- Direct conversion to the main hardness measurement scales HRC-HRB-HV-HB-HSD-HL

- The instrument is supplied complete with with a sample block for checking and calibrating the instrument

- Strong metal external structure and large backlit LCD screen

- Measurement possible in any direction

- Equipped with internal data memory and management and transfer software to PC

Further information

Impact hardness tester for metals ARW-220

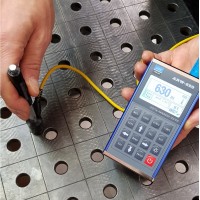

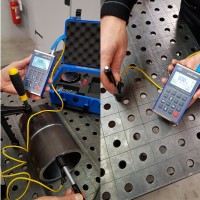

Compact and easy to use portable digital hardness tester, particularly suitable for measuring hardness on solid surfaces, even large ones, which are difficult to access with other instruments.

It uses the rebound measurement method (Leeb test) with an impact tester (probe) able of detecting the hardness on various types of material and converting the value into the main measurement scales (Rockwell B, Rockwell C , Brinell, Vickers).

Main features Portable Durometer ARW-220

- Calibration block included in the supply

- Rebound measurement system (Leeb Test), Standard “D” type impact probe included

- Selectable measurement scales: Rockwell (B & C), Vickers (HV), Brinell (HB), Shore (HSD) Leeb (HL)

- Strong metal external structure

- Large backlit LCD screen (128×64), with all functions and parameters

- Internal menu in "English"

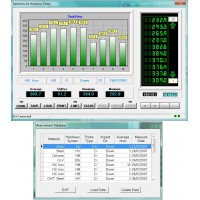

- Internal data memory for 500 measurement groups, with 32 single values for each group

- Mini statistics function: indicates the measured value, average value, direction of measurement, date and time

- Data interface, cable and software included in delivery (DOWNLOAD SOFTWARE FOLDER)

- Limit value function: A visual and acoustic signal helps the measurement

- Automatic recognition of the type of sensor used

- Ability to measure in any direction, vertical, diagonal, horizontal and upside down

- Auto power off for energy saving

|

Technical specifications Durometer for metals ARW-220 |

|

|

HL Display |

170 to 960 HLD (Standard “D” type probe) |

|

Precisione |

1% (on 800 HLD) |

|

LCD |

Backlit LCD (128x34mm) |

|

Accuracy |

1 HL, 1 HV, 1 HB, 0.1 HRC, 0.1HRB, 1 HSD |

|

Minimum weight of the tested sample |

3Kg (probe type “D”) |

|

Minimum thickness of the tested sample |

30mm (probe type“D”) lower in case of use of low impact “C” type impact instrument |

|

Minimum radius of the tested sample |

50mm (concave/convex) 10mm with the use of the adapter ring (supplied) |

|

Data storage |

For 500 measurement groups, with 32 individual values for each group, from which the average value is calculated |

|

Direction of measurement |

All direction possible, 360° (◄▲►▼) |

|

Operating conditions |

Ambient temperature -10 °C/40 °C, Humidity ≤90% |

|

Storage temperature |

-10°C to + 60°C (14 to 140°F) |

|

Power supply |

1,5V AA batteries (autonomy approx. 100h without backlighting) |

|

Dimensions |

132mm x 82mm x 31mm (5.9 x 3.1 x 0.9 inches) |

|

Weight |

ca. 600g (Probe excluded) |

|

Supply kit |

- Body instrument - Standard "D" type impact probe - Standard calibration block - Probe cleaning brush - Interface cable and software DataView (DOWNLOAD SOFTWARE FOLDER) - User manual - ABS case |

|

Fields of measurement |

|||

|

Stairs |

Materials |

Min |

Max |

|

Steel and steel alloys |

HRC |

19,8 |

68,5 |

|

HRB |

59,6 |

99,6 |

|

|

HSD |

26,4 |

99,5 |

|

|

HB |

140,0 |

651,0 |

|

|

HV |

83,0 |

976,0 |

|

|

Cutting tools |

HRC |

19,8 |

68,5 |

|

HV |

83,0 |

976,0 |

|

|

Stainless steel |

HRB |

59,6 |

99,6 |

|

HRC |

19,8 |

68,5 |

|

|

HB |

140,0 |

651,0 |

|

|

HV |

83,0 |

976,0 |

|

|

Cast iron |

HB |

140,0 |

334,0 |

|

Nodular cast iron |

HB |

140,0 |

387,0 |

|

Aluminum alloys |

HB |

30,0 |

159,0 |

|

Brass (copper and zinc alloys) |

HB |

40,0 |

173,0 |

|

HRB |

13,5 |

93,3 |

|

|

Bronze (copper alloys - aluminum - tin) |

HN |

60 |

290 |

|

Copper alloys |

HB |

45,0 |

315,00 |

Batting instrument impact

The Leeb rebound method is one of the four most used methods for determining the hardness of a metal and the Leeb measurement scale (HL) It is defined by the ratio of the speed of the impacting dart contained inside the impact instrument (Probe measurement) before and after the impact with the specimen. The dart, typically composed of tungsten carbide (synthetic diamond in probes for very hard materials), is loaded by the spring in the probe and "fired" against the specimen, on which it bounces off, losing energy due to plastic deformation. The speed of the dart is calculated at 1mm from the surface of the specimen and the harder the material, the higher it will be. To calculate the speed, a coil wound at the end of the probe is used on which the magnetized dart produces a voltage as it passes. directly proportional to its speed. Through suitable conversion tables, depending on the material on which the test is carried out, it is possible to convert the Leeb scale into the major other hardness scales, such as HV, HRC, HRB and HB.

Downloads